Robust, resistant, durable, high-tech

Every detail makes the system great

Propeller

It is the most important and the most delicate component of the wind machine. Its aerodynamic efficiency, closely linked to its proportion, determines the amount of air drawn from above and pushed down, and consequently the size of the protected surface. Designed and tested in wind tunnels, measured with analogue models and field tests, it moves large volumes of air at low speed to ensure maximum distance of air movement.

It can be manufactured in fiberglass, to enhance stress resistance, or in carbon fiber, to make it lighter and reduce the stress on the gearbox. The external surface is protected by special paints that make it resistant to atmospheric agents.

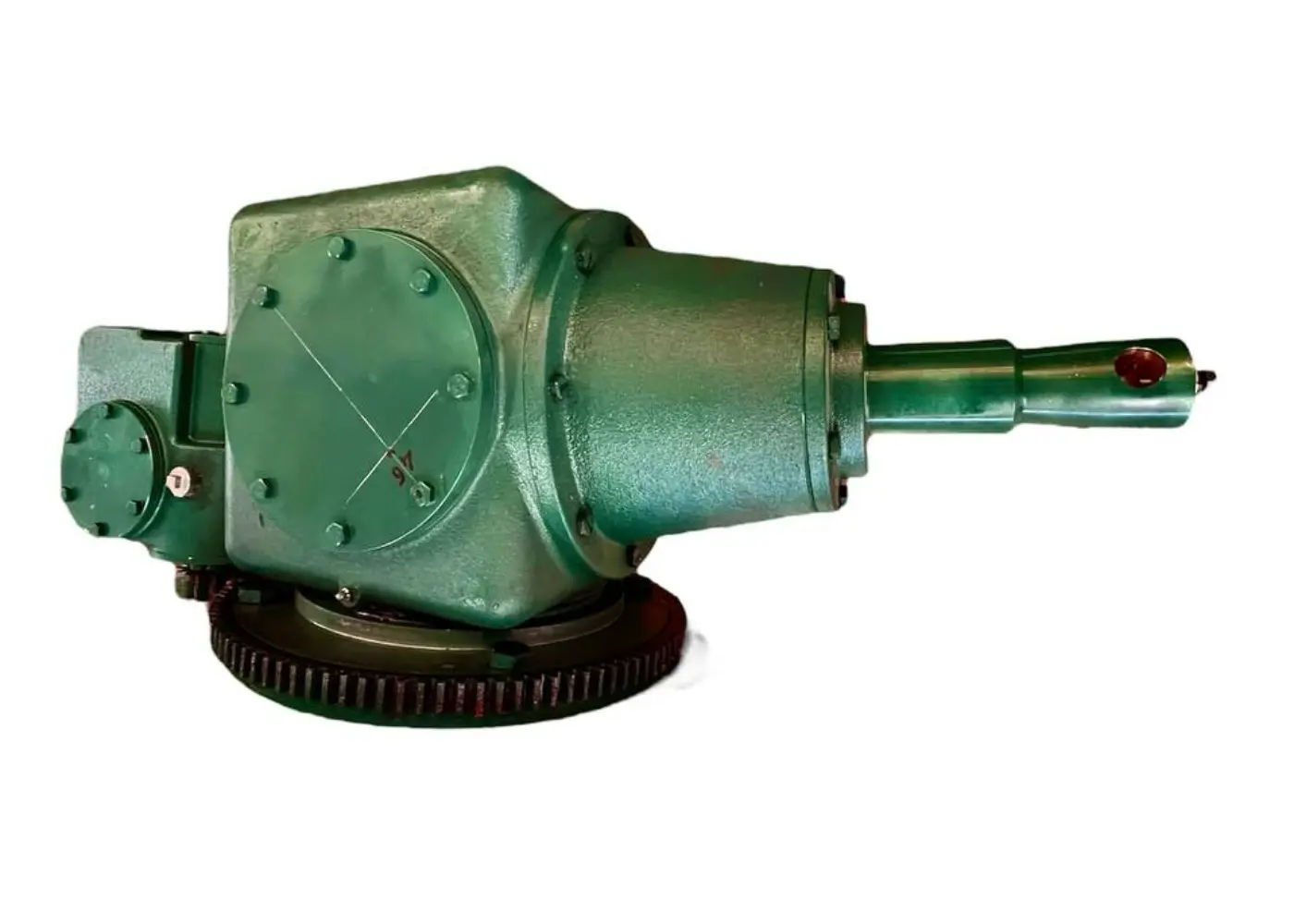

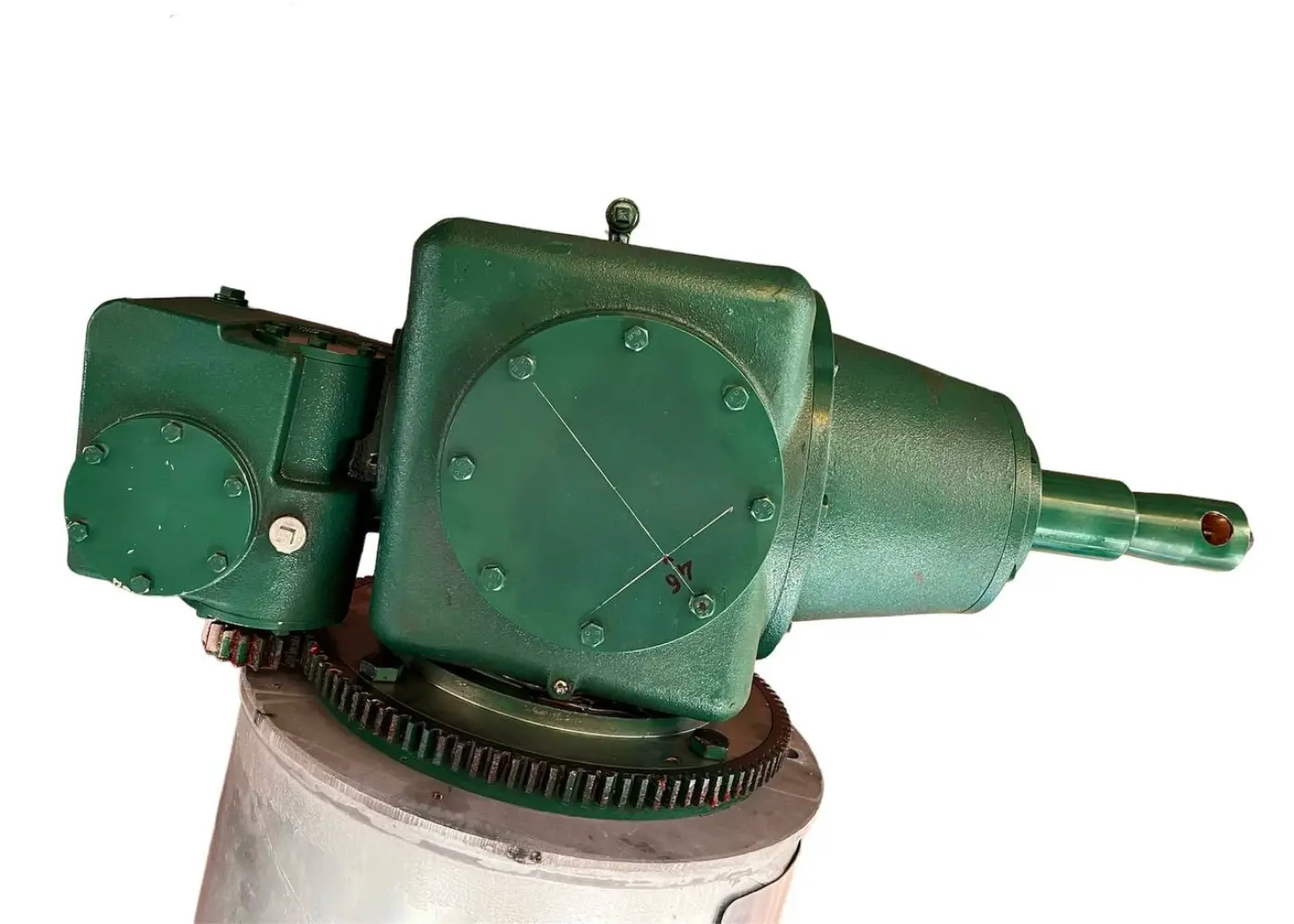

Upper Gearbox

The upper gearbox is made with a cast iron one-piece crankcase, as the lower gearbox, and a pair of straight bevel gears with 2,16:1 gear ratio. The drive shafts are in hardened and cemented steel and they are mounted on large bearings to support the axial and radial thrust of the propeller.

The revolution of 360° of the upper gearbox is carried out with a planetary gearbox mounted inside the tower, which is coupled to the main drive shaft through a toothed belt. The revolution time is 5 minutes to ensure the most effective mixing of the warmer air layers with the lower ones through the forced convention effect of the vortex generated by the propeller.

Tower

Consisting of an electro-welded steel tube, the tower houses the vertical drive shaft, made of steel and supported by 6 self-aligning bearings that eliminate any vibration during operation.

The vertical drive shaft is connected to the lower gearbox with a non-lubricated star joint and high strength rubber buffer which ensure torsional stresses. In the upper part the vertical drive shaft is connected with the upper gearbox through a joint with rounded profile teeth and a ferrule made of steel or polyamide. This allows the tower to absorb the axial and radial adjustments of the drive shafts caused by thermal variations without stressing them.

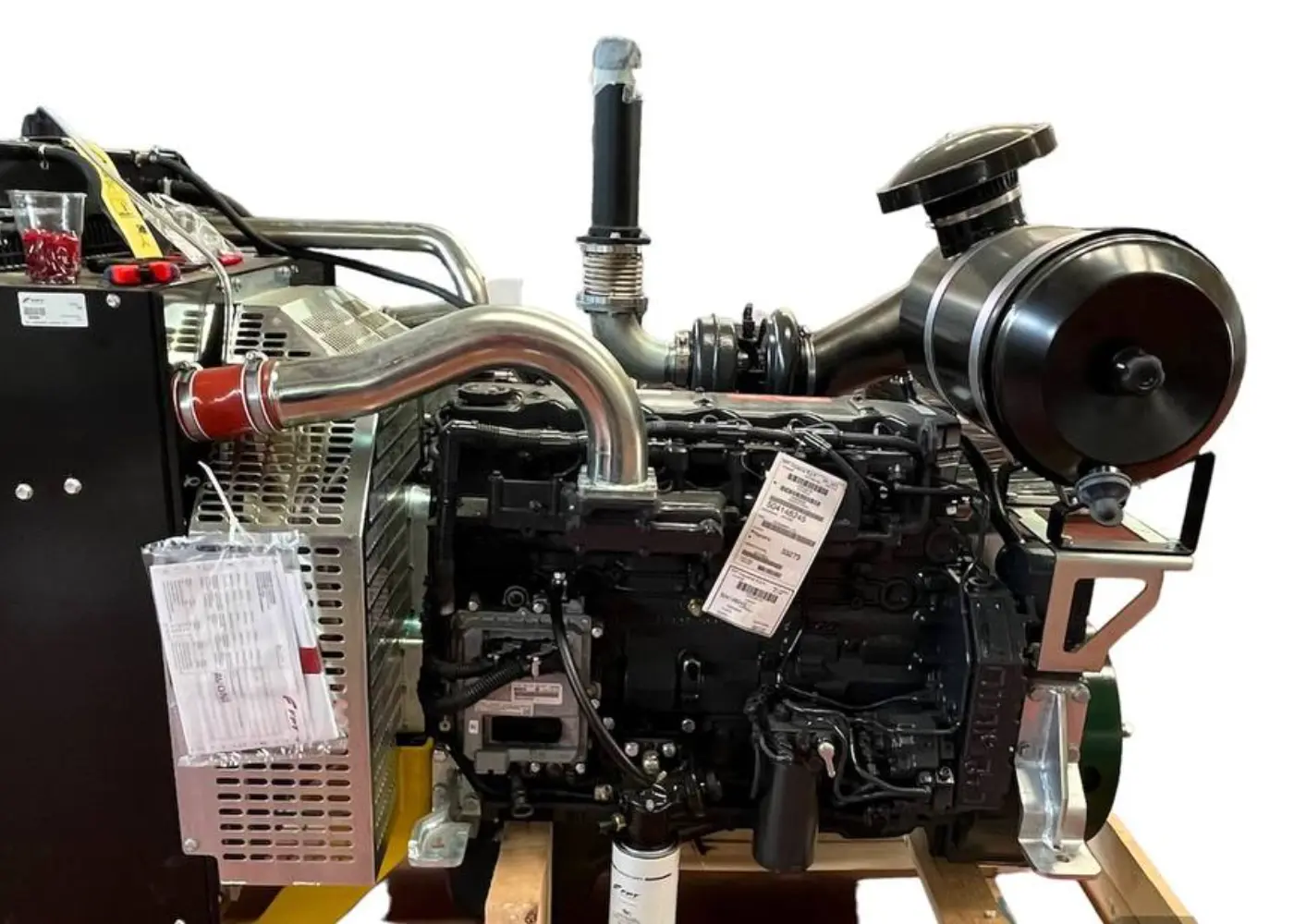

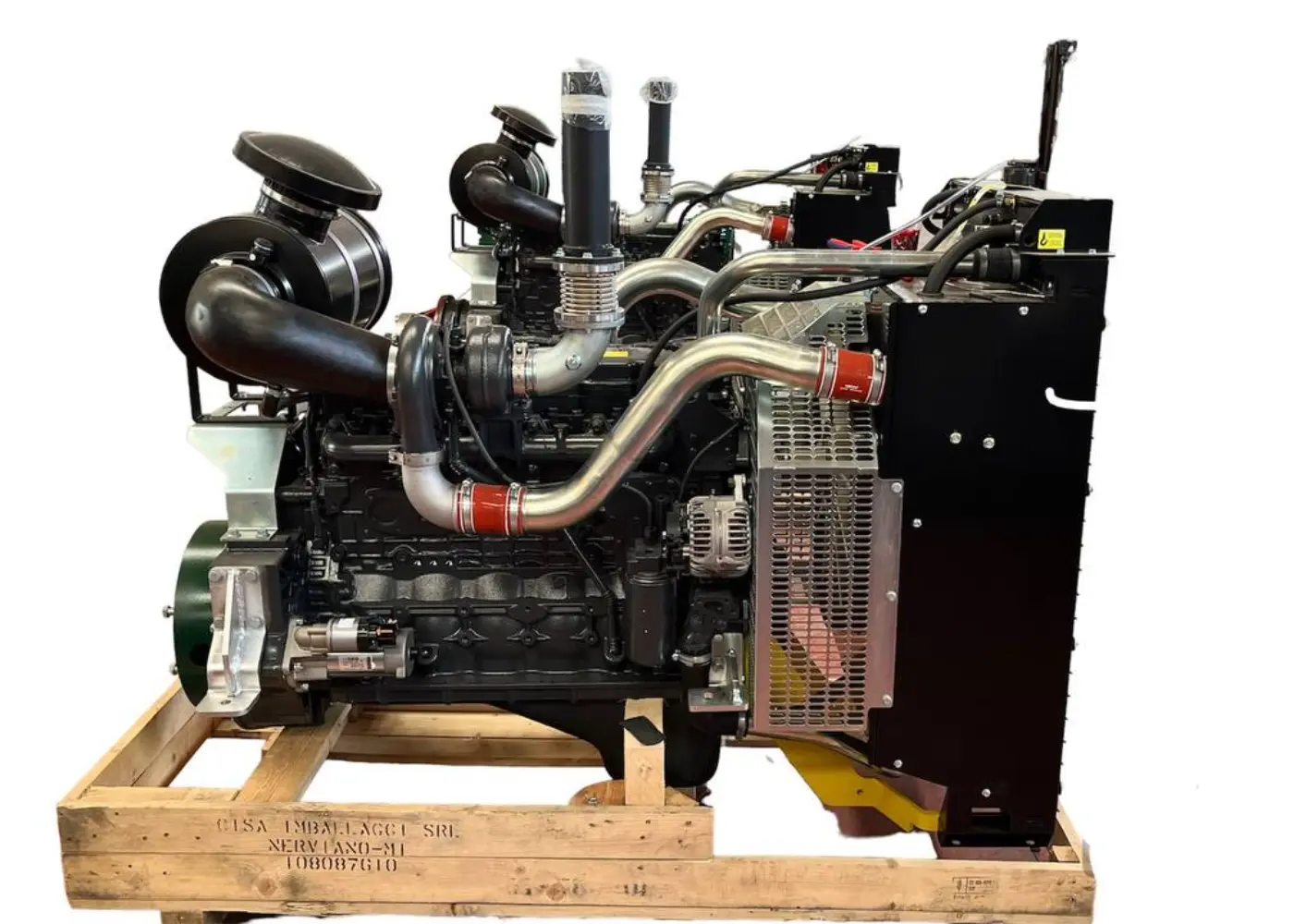

Engine and Electronic Control

The electronic control panel monitors the starting of the engine at the pre-set external temperature from 0°C to +2°C, according to the kind of crop, the time of year and whether it is necessary to protect the fruit or the blossom.

The electronic controller is programmed by a microprocessor that controls the start and speed of the engine based on the external temperature measured by a PT 100 platinum sensor with a temperature range from -10°C to +10°C.

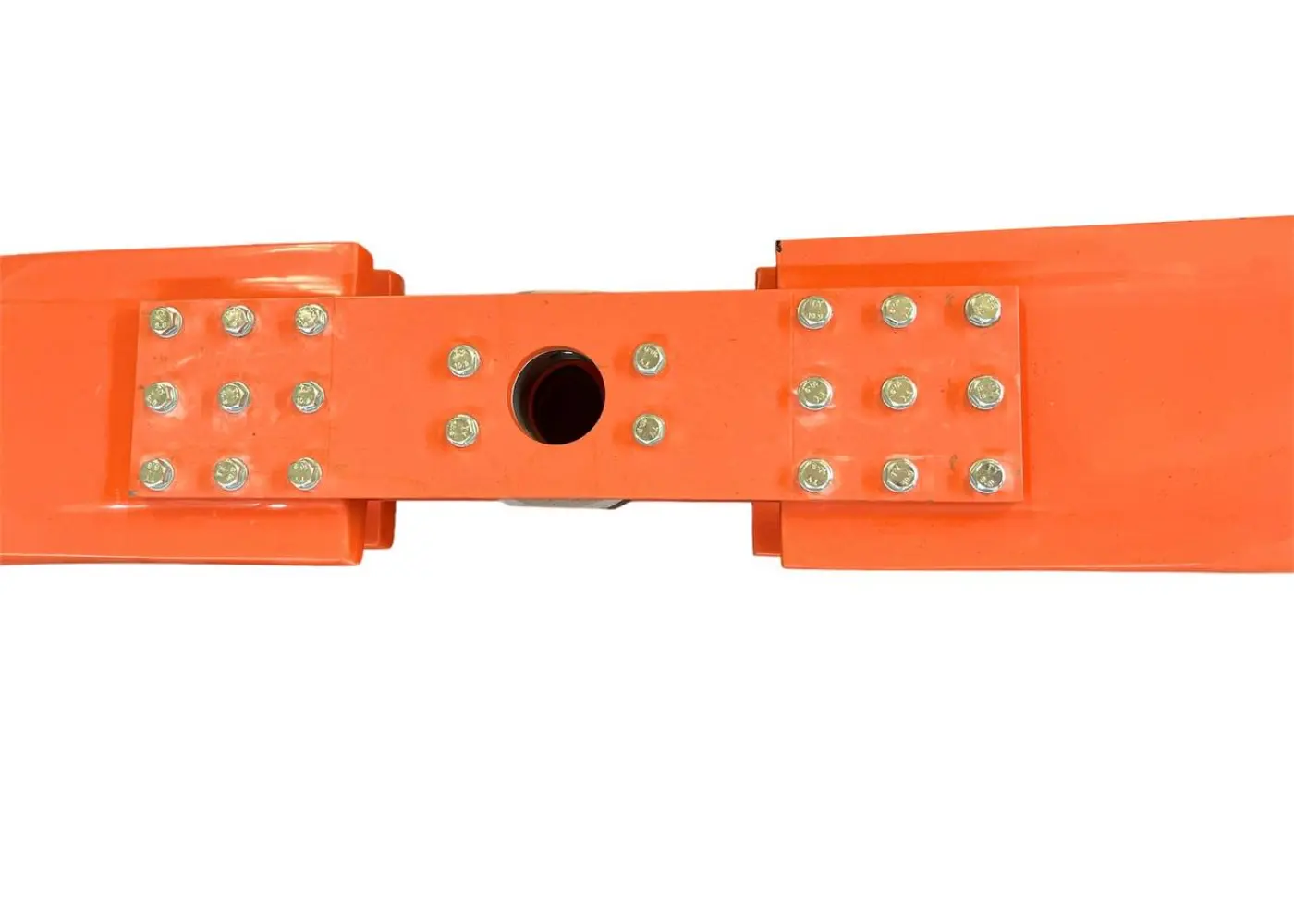

Lower Gearbox

The Lower gearbox is made with a high-resistance ductile iron one-piece crankcase and with a pair of bevel gears with Gleason teeth in hardened and cemented steel with 2:1 gear ratio.

The drive shafts are in hardened and cemented steel and they are mounted on roller bearings to support axial and radial loads, with Viton sealing rings. The gears operate in an oil bath to ensure perfect lubrication. The lower gearbox is coupled with the propulsion motor through a dry clutch or a hydraulic joint.